Fouling can cause up to 20% of efficiency loss in compression, and 70% efficiency loss in absorption chillers. The result in both cases is increased cost of operation.

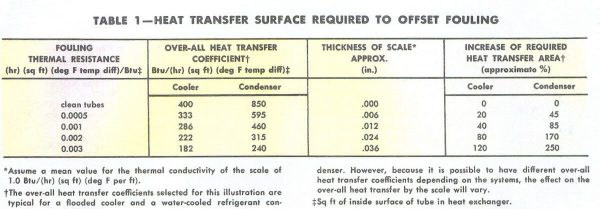

In studies made by CarrierTM it was determined that a scale of 0.15 mm thickness in a condenser would require an increase of 40% in the heat exchange area in order to provide the same heat exchange rate. In other words, a 0.15mm scale reduces the heat exchange efficiency by about 40%.

Source: Carrier Handbook Chapter 1. Water Conditioning General

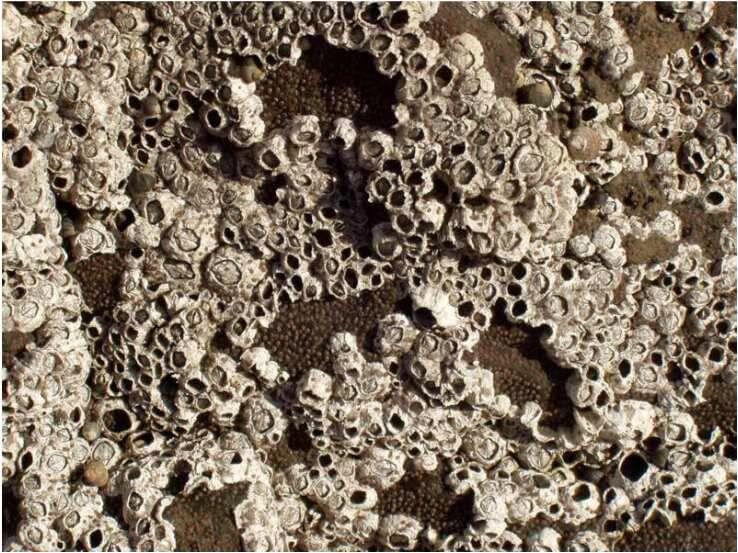

Fouling is the deposition and accumulation of unwanted materials such as scale, algae, biofilm, mussels, organic matter and insoluble salts on the internal surfaces of heat exchangers.

When cooling systems operate, water with fouling factors flow through the system: Hard water causes scaling, whereas seawater can cause biofilm, or growth of micro and macro species. Soft at first, fouling becomes hard if not treated and prevents the proper operation of the system. Although ATCS systems are very efficient in preventing micro and macro fouling in tube &shell type heat exchangers, CQM’s SRSW Seawater disinfection systems provide an efficient solution for plate heat exchangers.

As fouling increases, two things occur: First, the volume of water that can flow through the heat exchanger is reduced. Second, the deposited matter adds as an isolation layer reducing the efficiency of the heat exchange.

Heat exchange efficiency reduction translates to wasted energy in screw / compressor chillers: The less efficient the heat transfer, the more energy the chillers require in order to provide the same level of cooling. Typically, the energy wasted due to untreated fouling varies between 10 – 20 % of the energy required by the chillers.

While in electrical chillers fouling can be compensated by an increase in energy, absorption chillers are more delicate. Fouling at the absorber and the condenser reduce the efficiency of the chiller up to 70%, and the chiller simply cannot provide the required cooling, and additional electric chillers must be operated.

With the use of ATCS, CQM guarantees that the tubes will remain free of any fouling.