Improved Operational Efficiency and up to 30% Energy Savings

Automatic Heat Exchanger Cleaning Process

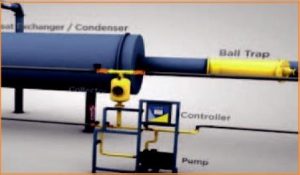

The balls start out in a collector that is connected to the heat exchanger or condenser through the main line of the system. A window in the collector enables seamless monitoring of both the condition and number of balls inside.

The ATCS includes a PLC controlled pump which forces water through the pipes. Once the water enters the collector, the system periodically injects all of the balls into the inlet pipe. Following the injection, normal system water flow carries the balls through the inlet pipe and into the main line.

The balls proceed from the main line to the condenser, where they are randomly distributed across the condenser tubes.

The balls then flow through the tubes at normal system flow velocity. As the balls are pushed though the pipes by the water, the balls clean off residue, deposits and buildup before any fouling results.

As the balls exit the condenser, they are collected in a ball trap with no moving parts, and no possibility for the balls to escape.

Once the balls are in the trap, the controller opens the drain valve and the balls are carried back to the collector. At this point, they are rinsed clean by circulating system water which is directed through the collector. The collector then holds the balls until the next cycle.

The Problem of Fouling in Heat Exchangers

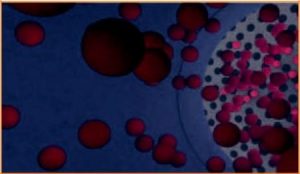

“Fouling” is an undesirable piled deposit formed inside a condenser, sometimes described as a thermal resistant on the heat path in the condenser. The thermal resistance is proportional to the thickness of the deposit, and is in inverse proportion to the thermal conductivity of this deposit. In the past, condenser cleaning involved long shutdowns, harmful chemicals and ongoing operating expenses.

Automatic Tube Cleaning System – Heat Exchanger Cleaning

CQM has developed a remarkably simple system in which recycled cleansing balls are flushed through the cooling system via a natural water flow, ensuring that unwanted deposits and residue are cleaned before fouling occurs. With the installation of CQM’s ATCS, the internal surface of the cooling tubes are guaranteed to remain clean, resulting in improved heat transfer and reduced energy consumption. The ATCS is fully automatic (PLC controlled) and works continuously while the heat exchanger is operational, eliminating the need for inconvenient shutdowns or costly maintenance.

Innovative Tube Cleaning System

CQM’s recycled cleansing balls result in:

- Energy savings of up to 30%

- Elimination of costly downtime

- Extension of capital equipment life-cycle

- Optimization of heat transfer performance